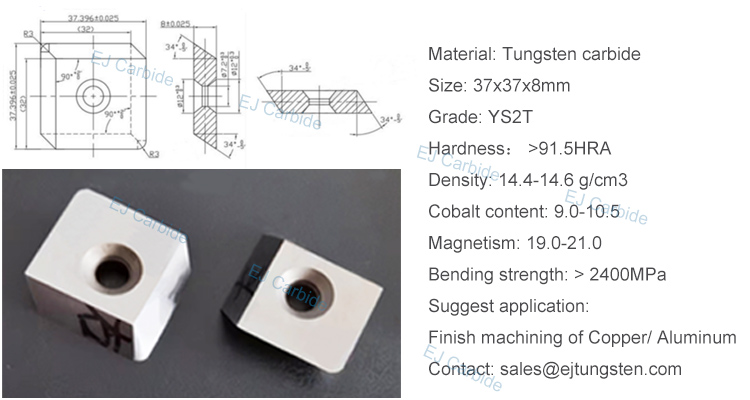

Because of its small density (about 2.7gcm3), high specific strength (about 1.35gpa), high thermal conductivity (about 0.067wm•k), and high resistivity (about 1015ω.mm2), aluminum plays an important role in our daily life. It is very common in mechanical processing, and blade milling cutters for cutting aluminum materials are also one of the most commonly used cutting tools. How to use the special milling cutters for end milling, copy milling and other equipment correctly? Come and follow us today EJ Carbide Co., Ltd to find out

Based on our experience and feedback from customers, we have summarized the following points

1. The milling cutter cannot be used for work other than the specified purpose, otherwise the use effect will be affected, and abnormal phenomena such as milling cutter damage will occur.

2. The workpiece to be cut when the milling cutter is in use must be fixed to avoid abnormal cutting, resulting in damage to the milling cutter, flying debris and personal injury and property loss.

3. The milling cutter must feed the material in a straight line when cutting, and the material must not be pushed in forcibly, otherwise the milling cutter will be damaged due to excessive feeding, the fragments will fly, and personal injury and property loss will occur.

4. When the milling cutter is cutting, confirm that there is no foreign matter such as steel on the workpiece to be cut, otherwise the milling cutter will be damaged.

5. If the milling cutter vibrates abnormally during cutting, and the cutting surface is rough or curved, the operation must be stopped to check the equipment and troubleshoot in time.

6. Appropriate feed rate. If the feed speed is slow, the work efficiency will be low. If the feed speed is too fast, the service life of the blade will be reduced and the processed surface will be uneven.

7. It is recommended to use a special coolant for cutting, which is characterized by smokeless, non-toxic, and tasteless. It can not only play a cooling role but also a lubricating role, and the service life of the saw blade can be extended by one third.

8. When storing the milling cutter, it must be placed vertically. It is forbidden to place sundries on the milling cutter to avoid deformation.

9. When the milling cutter is not sharp, it must be ground. When grinding, it must be done by a professional manufacturer, and the original angle cannot be modified.

The above are some of my experience from our Yijie Cemented Carbide Co., Ltd. If it can help you, we are very honored. If you have other questions or needs about aluminum processing blades, please contact us at +86 18673339477 or info@ejcarbides.com